Services

Prices and details upon request

- All

- ACT

- creep tensile tests

- FNCT

- Internal pressure tests

- Material properties

- Notched Pipe Test (NPT)

- Point Load Test (PLT)

- Point Loading Test under accelerated test conditions (PLT+)

- Scratch test

Accelerated Creep Test (ACT)

The PE 100-RC materials described in PAS 1075 are characterized by very high stress crack resistance. The verification of the stress crack resistance of PE 100-RC materials requires an acceleration of the testing procedure.

The FNCT under Accelerated Creep Test conditions (ACT) was developed by HESSEL Ingenieurtechnik with the aim of accelerating the characterization of the stress crack behavior of PE 100-RC materials.

The ACT is an internationally established testing procedure and is preferred for reliable quality control and batch release.

Point Loading Test under accelerated test conditions (PLT+)

The PE 100-RC materials described in PAS 1075 are characterized by very high stress crack resistance. The verification of the stress crack resistance of PE 100-RC materials requires an acceleration of the testing procedure.

The PLT under accelerated test conditions (PLT+) was developed by HESSEL Ingenieurtechnik with the aim of accelerating the characterization of the stress crack behavior of PE 100-RC pipes.

The PLT+ is an internationally established testing procedure to demonstrate suitability for alternative installation methods.

Tests according to PAS 1075

Pipes made from Polyethylene for alternative installation techniques - Dimensions, technical requirements and testing

- Annex 1: FNCT (accelerated test conditions)

- Annex 2: 2NCT (accelerated test conditions)

- Annex 3: Point Loading Test (accelerated test conditions)

- Annex 4: Penetration Test

- Annex 5: Thermal Ageing Test

- Annex 6: External Protective Layer Scratch Test

Tests according to DIN EN ISO 527-2

Plastics - Determination of tensile properties - Part 2: Test conditions for moulding and extrusion plastics

Tests according to DIN EN 12201-1

Plastics piping systems for water supply, and for drainage and sewerage under pressure - Polyethylene (PE) - Part 1: General

Tests according to DIN EN 12201-2

Plastics piping systems for water supply, and for drainage and sewerage under pressure - Polyethylene (PE) - Part 2: Pipes

Tests according to DIN EN 12814-3

Testing of welded joints of thermoplastics semi-finished products - Part 3: Tensile creep test

Included:

- Annex A.1: Tensile creep test on specimens with circumferential notch (FNCT)

- Annex A.2: Tensile creep test on specimens with 2 notches (2NCT)

- Annex B: Whole pipe tensile creep rupture test

- Annex D: Testing of socket joints

Note: The following translations of Annexes A.1, A.2 of the standard DIN EN 12814-3 are our own translations and not the original text.

Tests according to DIN EN 1555-1

Plastics piping systems for the supply of gaseous fuels - Polyethylene (PE) - Part 1: General

Tests according to DIN EN 1555-2

Plastics piping systems for the supply of gaseous fuels - Polyethylene (PE) - Part 2: Pipes

Tests according to DIN EN 253

District heating pipes - Bonded single pipe systems for directly buried hot water networks - Factory made pipe assembly of steel service pipe, polyurethane thermal insulation and a casing of polyethylene

Tests according to DIN EN ISO 1133-1

Plastics - Determination of the melt mass-flow rate (MFR) and melt volume-flow rate (MVR) of thermoplastics - Part 1: Standard method

Tests according to DIN EN ISO 11357-6

Plastics - Differential scanning calorimetry (DSC) - Part 6: Determination of oxidation induction time (isothermal OIT) and oxidation induction temperature (dynamic OIT)

Tests according to DIN EN ISO 1183-1

Plastics - Methods for determining the density of non-cellular plastics - Part 1: Immersion method, liquid pycnometer method and titration method

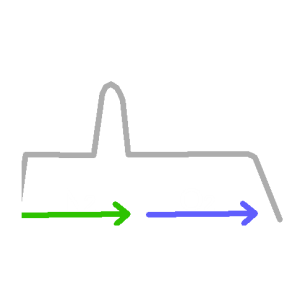

Tests according to DIN EN ISO 13479

Polyolefin pipes for the conveyance of fluids - Determination of resistance to crack propagation - Test method for slow crack growth on notched pipes

Tests according to DIN EN ISO 179-1

Plastics - Determination of Charpy impact properties - Part 1: Non-instrumented impact test

Tests according to DVS 2203-4

Testing of welded joints of thermoplastics plates and pipes - Tensible creep test

Supplement 1

Testing of socket jointsSupplement 2

Tensile creep test for resistance to slow crack growth in the full notch creep test (FNCT)Supplement 3

Checking the required tensile creep test weld strength reduction factor and the minimum service life of polyethylene welded joints (PE 80 andPE 100)Supplement 4

Tensile creep test for resistance to slow crack growth in the two notch creep test (2NCT)

Tests according to ISO 16770

Plastics - Determination of environmental stress cracking (ESC) of polyethylene - Full-notch creep test (FNCT)

Tests according to ISO 4433-1

Thermoplastics pipes - Resistance to liquid chemicals - Classification - Part 1: Immersion test method